Water Cooled Screw Chiller

|

|

|

Water Cooled Screw Chiller Features

| A water-cooling system assures the stable supply of cold water. HITACHI offer water cooled screw chiller with various refrigerant R-407c, R-410a and R- 134a which functions well in applications such as the cooling of production process lines in manufacturing plants, as well as in conditioning of commercial spaces. Hitachi is the world 's first to introduce semi-hermatic screw compressors in the world. |

| Hitachi also offers Low-temperature and Heat Recovery Chillers for medical, pharmaceutical industries , Hotels, Hospitals and various industrial process cooling applications like plastic mould cooling, printing and lamination processes. These chillers incorporate microprocessor based controls which offer intelligent cooling and are energy efficient. |

Key Features

| Range | 50 HP, 60 HP, 80 HP, 100 HP, 125 HP, 150 HP & 190 HP | ||||||||

| Key Features (USPs) |

|

||||||||

| *The above key features are only avaialble in CW_VRF3E Model Series | |||||||||

Product features and Benefits

| Advantages | Benefits |

|---|---|

| High Performance Screw Compressor | Energy Saving with High Efficiency |

| Continuous Capacity Control | Precise Capacity Control & better partload achievement |

|

Simple Structure and High Technology by inhouse manufacturing |

High reliability |

| Modular System | Easy Maintenance and Better Redundancy |

| Safety Devices Equipped as Standard | Protect the unit from abnormal operation for longer life span |

| Cyclone oil seperator | Very less oil carry over to copmpressor |

| Heat recovery | Free of cost Hot water generation |

Energy Saving

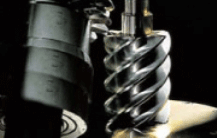

| High Performance A-Type Screw Compressor | |

|---|---|

|

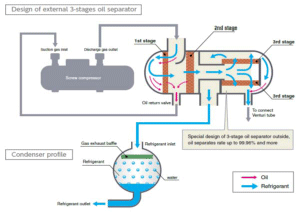

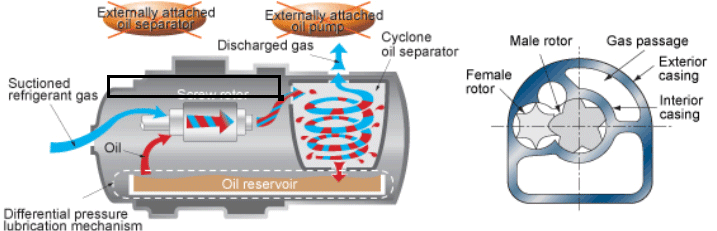

Built-in Cyclone Oil Separator for dry expansion chiller Low oil carrying-out is realized and reduction of heat transfer efficiency is minimized. HITACHI high efficient external 3 stage oil seperator having up to 99.96% oil seperation. |

|

|

No outside pump is required due to the reliable differential-pressure oil-feeding system This oil-feeding system, which does not use any electrical mechanism, prevents the compressor from being damaged and maintains long-term stable operation. |

|

|

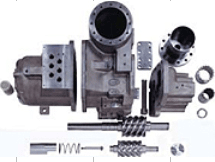

High Technology by Internal Manufacture Because all manufacturing processes, from rotor manufacturing to unit assembly, are done internally, exceptional reliability is achieved. |

|

|

Low Vibration, Low Noise Without the conventional demister chamber system, no noise is produced during oil separation of discharge gas. A vibration-proof base is not required for the chiller body thanks to the firmly-secured, lowvibration screw compressor. |

|

|

|

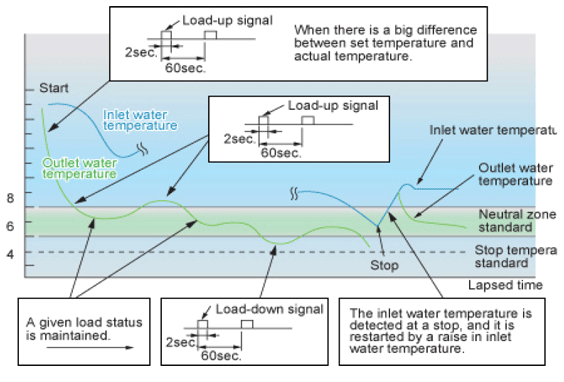

Precise Capacity Control

| Continuous Capacity Control |

|---|

| The temperature of the chilled water outlet can be kept at the set temperature ±1°C by continuous capacity control, so it is suitable for industrial use. |

|

High Reliability

| Simple Structure and Small Number of Parts | |

|---|---|

| Whereas the number of main parts for the casing, compression mechanism and capacity control mechanism of a reciprocating compressor is 268, that of a screw compressor is only 27, just one tenth of the number. A structure with so few parts offers high reliability and easy maintenance. |

|

| High Technology by Internal Manufacture | |

| Because all manufacturing processes, from rotor manufacturing to unit assembly, are done internally, exceptional reliability is achieved. |

|

Easy Maintenance

| Modular System | |

|---|---|

| Hitachi chiller units feature a modularization cycle structure, so each module can be packed and transported individually, for more convenient local installation and displacement. Furthermore, the refrigerant system of each module can be operated independently, which makes maintenance easier. | |

|

|

Compact and Light Weight

| The Volume, installation space and weight are all reduced, making installation easy. |

|---|

Safety Devices Equipped as Standard

| The Hitachi chiller is equipped with several safety devices as standard. Those safety devices protect the unit from abnormal operation for higher reliability and longer lifespan of the chiller. | |

|---|---|

| List of Safety Devices | |

| Three-Phase Over-current Relay | Fusible Plug |

| High-Pressure Switch | Freeze Protection Thermostat |

| Low-Pressure Switch | Reverse Phase Protection Relay |

| Oil Heater | Discharge Gas Thermostat |

| Internal Thermostat for Comoressor Motor | Operation Hour-Meter and Safety Valve |

Water cooled screw chiller with heat recovery option

| Hitachi Water-cooled screw chiller with heat recovery option is added advantage which can generate hot water upto a max. temperature of 55°C without any increase in operating cost of the chiller. The heat recovery is practically at zero operating cost, alternately meaning a substantial increase in the efficiency of the water chiller. The amount of heat recovery is a direct saving, thus increasing the efficiency considerably. |

|---|

Water cooled screw chiller - Line up

| Water Cooled Screw Chiller - Line Up. [ HP ] | |||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| R-407C | 40 | 50 | 60 | 80 | 100 | 120 | 140 | 150 | 170 | 180 | 200 | 220 | 260 | 300 | 340 | 380 | 410 | 450 | 490 | 530 | 570 |

| R-410a | 160 | 220 | 280 | 300 | 380 | 440 | 500 | 560 | 600 | 660 | 720 | 780 | 840 | ||||||||

| R-134a | 140 | 185 | 230 | 280 | 330 | 370 | 420 | 460 | |||||||||||||

| New Range (R134a) | 50 | 60 | 80 | 100 | 125 | 150 | 190 | ||||||||||||||

Hitachi water cooled brine chiller option available for the minus (-'C) application.